Bring the taste of fresh, hand-made Japanese noodles to your shop.

SETO TS-1P & Super Mix SS-8P

Make up to 250 servings of fresh Japanese noodles every hour.

With Sanuki Menki's SETO TS-1P and Super Mix SS-8P, you'll never have to put up with inferior quality noodles bought from wholesalers. Instead, you'll be able to easily make fresh, high-quality noodles inside your very own shop.

A Complete Noodle-Making Setup Inside Your Shop

The Super Mix SS-8P is a compact mixing unit. It blends wheat flour and water with consistency and precision to create a perfect dough mixture. The SS-8P has a 8kg capacity, making it perfect for use with the SETO TS-1P.

The SETO TS-1P rolls the dough mixture from the SS-8P into smooth dough sheets and then cuts them into noodles of any size. The SS-8P and SETO TS-1P are a complete, compact system for making fresh, high quality ramen, soba or udon from scratch.

Make Different Types of Noodle With The Same Unit

The SETO TS-1P is a compact but versatile machine. Different types of noodles can be made simply by changing the cutting unit. All popular Japanese noodles including ramen, soba and udon can be made using this unit.

Compact Size Means It Fits Into Any Shop

The compact size of the SETO TS-1P and Super Mix SS-8P makes it suitable even for small shops.

This means that all restaurants are able to benefit from serving their customers high quality, freshly-made noodles.

Caster wheels also makes each unit easy to move around in the shop.

Keep Up With Demand

When paired with the Super Mix SS-8P, the SETO TS-1P is capable of making between 150 – 250 servings per hour – enough to keep up with virtually any restaurant.

Better Quality Noodles For Less

The SETO TS-1P provides you with an inexpensive way to improve the quality of your noodles and set yourself apart from other restaurants who bring in inferior quality, mass-produced noodles.

With the SETO TS-1P, the cost of producing noodles is only around 15c per serving.

Making Fresh Noodles Using The SETO TS-1P & SS-8P

Mixing Dough With The Super Mix SS-8P

The Super Mix SS-8P Dough Mixer

Steps

1. Load flour into the SS-8P.

2. Pour the correct amount of water onto the special draining lid. This draining lid slowly drizzles the water into the flour mixture, ensuring a consistent dough blend.

3. Turn the mixer on and the dough will start mixing.

The mixer can hold a maximum of 8kg flour. A minimum of 1kg of flour should be used each batch. The dough will be mixed in approximately 20 – 30 minutes.

When the batch has finished mixing, undo the latch on the right hand side and tilt the drum down. Turn the mixer on again to discharge the dough mixture into a container.

Making Noodles With The SETO TS-1P

The SETO TS-1P

The SETO TS-1P

Steps

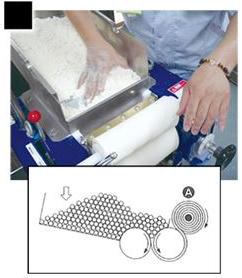

1. Transfer the dough mixture into the SETO TS-1P.

2. Make sure the lever on the top left hand side of the machine is set to 'rolling'. Turn the machine on. The dough mixture will be pressed into a sheet. Feed the sheet onto the winder as it rolls.

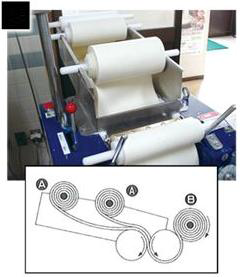

3. Next, compound the dough. Take the rolled dough sheet and wind it onto 2 separate winders to create 2 separate sheets.

Feed these two sheets together into the roller. This will create a compounded dough sheet.

Compounding gets rid of gaps and holes in the sheet and creates a much more consistent dough texture. It also accelerates gluten development.

4. Place the dough in a plastic bag and age for 30 – 60 minutes.

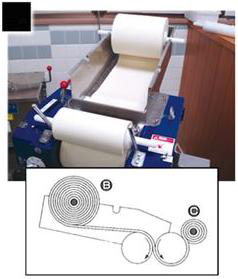

5. After the dough has been aged, press it into the right thickness using the SETO TS-1P. The thickness of the sheet can be adjusted using the dials on the front panel.

6. The dough sheet is then cut to make noodles. Change the top left lever from 'rolling' to 'cutting.' Feed the dough sheet into the top of the machine and the finished noodles will fall onto the bottom conveyor where they can be collected and placed onto a tray.

The length of the noodles can be adjusted on the control panel.

7. The freshly prepared noodles can then be cooked and served.

About Sanuki Menki

Sanuki Menki is Japan's oldest noodle-making machine manufacturer, first formed in 1910. With its long history in Japanese noodle-making machine manufacturing, Sanuki Menki provides not only high quality machinery for all sizes of noodle manufacturers – from small noodle shops to large production lines – it provides unmatched expertise in the art of noodle production.

In addition to its machine manufacturing operation, Sanuki Menki runs the only government-approved noodle-making school in Japan. The school has taught over 38,000 people how to open and operate successful Udon, Soba and Ramen restaurants over the past 38 years.

Sanuki Menki is able to offer high quality Japanese-made machinery to make fresh noodles that rival the taste of traditional hand-made noodles. They then back this up with the knowledge, expertise and training to help you run a successful noodle business.

Technical Specifications

| Specifications | Detail |

|---|---|

| Model | SETO TS-1P |

| Machine Capacity |

100 – 250 servings / hour > 100 – 200 servings / hour for Ramen > 120 – 180 servings / hour for Soba > 200 – 250 servings / hour for Udon |

| Power Input | Single phase (100V) 50/60Hz |

| Power Consumption | 640W |

| Machine Dimensions | 650 W x 900 D x 1,125 H (mm) |

| Machine Weight | 240kg |

| Standard | Available in CE UL NSF CSA versions |

| Assembled & Manufactured In | Japan |

| Specifications | Detail |

|---|---|

| Model | Super Mix SS-8P |

| Machine Capacity | 8kg |

| Power Input | Single phase (100V) 50/60Hz |

| Power Consumption | 400W |

| Machine Dimensions | 700 W x 455 D x 880 H (mm) |

| Machine Weight | 80kg |

| Standard | Available in CE UL NSF versions |

| Assembled & Manufactured In | Japan |